What are Pressure Sensitive Adhesives (PSA)?

Pressure sensitive adhesives (PSAs), also known as self-stick adhesives, provide adhesion to a surface when pressure is applied, with no need for heat, water, or solvents to cement the bond. These adhesives provide strong tack at room temperature and can be removed and re-adhered, unlike other polymer adhesives that undergo permanent changes as they bond.

The unique qualities of PSAs make them suited to a wide range of adhesive products across industries, from tapes, labels, and bandages to electronics and automotive interiors. Valued at 12.74 billion USD in 2023, the global market for PSAs is expected to continue to expand (Grand View Research, 2024).

How PSAs work

The defining characteristic of a pressure sensitive adhesive is its permanent tack. Unlike structural adhesives, which undergo permanent, chemical changes as they bond to the substrate, pressure sensitive adhesives rely on their tack, or stickiness, to adhere to a surface.

How structural adhesives work

Structural adhesives may operate through chemical adhesion (formation of new chemical bonds with the substrate), mechanical adhesion (solidifying to lock into holes in the surface of the substrate, also known as the anchor effect), or diffusive adhesion (deep penetration of the adhesive polymer into the substrate through interdiffusion). These permanent changes may alter the substrate and make the adhesive difficult to remove and impossible to reuse.

Pressure sensitive adhesion

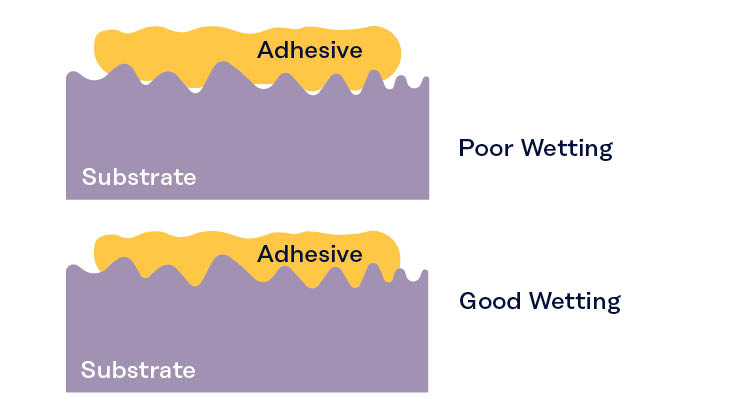

Pressure sensitive adhesives produce their tack primarily through van der Waals forces, which are intermolecular attractions that occur when the adhesive and substrate surface are brought into close contact. When the soft and pliable adhesive is pressed to the substrate, its molecules “wet” across the surface, the molecules of both surfaces are brought close together, and the van der Waals forces can work at maximum strength.

Since this force can be initiated with light pressure and can be counteracted by simply pulling the adhesive away from the surface, PSAs are readily removable and some are even reusable, typically maintaining their tack over multiple uses. These properties also enable PSAs to bond effectively, noninvasively—without damaging the surface—and instantly to almost any surface, with no need for a curing step during adhesion.

Types of PSA

Pressure sensitive adhesives are manufactured in several main forms for use across industries.

Adhesive tape

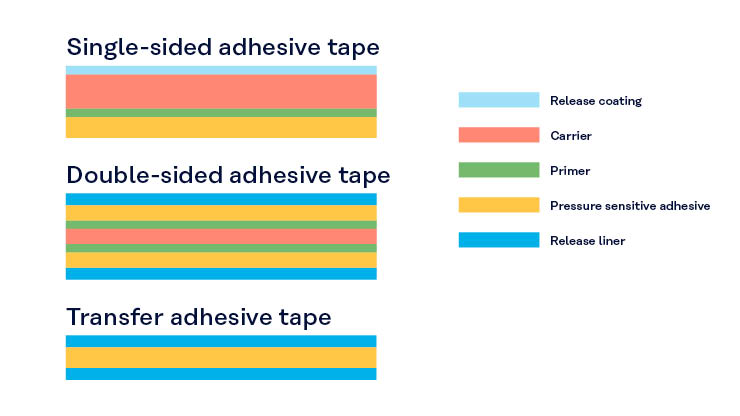

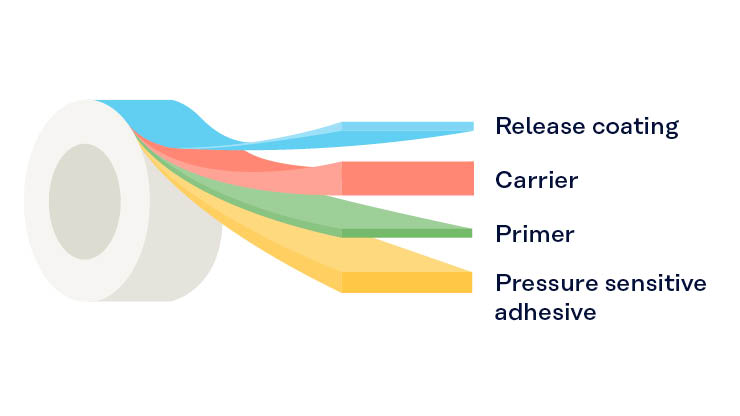

Adhesive tapes are rolls of a carrier that has been coated with PSA on one or both of its sides. These tapes are the most common examples of PSA application, including desk tape, duct tape, electrical tape, and more. The composition of the adhesive and carrier are often tailored to the tape’s application.

Single-sided vs. double-sided products

Single-sided (or single-faced, or single-coated) adhesive tapes are coated with pressure sensitive adhesive on only one of their sides, leaving the other side of the carrier bare. This exposes the carrier after application, not the adhesive, offering the tape more protection against weathering factors such as moisture, dust, and UV light.

Double-sided (or double-faced, or double-coated) adhesive tapes are coated with pressure sensitive adhesive on both sides of their carrier, offering a versatile solution for bonding two surfaces together while keeping the tape hidden between them.

Adhesive labels

Adhesive labels are used in most products and packaging, making them the most common PSA application on the market. These products, which also include stickers, graphics, printable films, and overlaminates, are composed of a carrier and PSA coating protected by a liner.

Transfer tape

Transfer tapes are rolls or sheets of adhesive with no carrier. Instead, each side of the free sheet of adhesive is protected by a liner that can be removed. This thin sheet of adhesive is used to seamlessly join layers of material such as fabric, plastic, printed circuit boards, and paper. Transfer tape is often used in electrical device assembly, graphic design, manufacturing, medical and healthcare, and consumer goods.

Printable films

Printable films are single-faced tapes that consist of a printable carrier, often made of PE, PP, PET, or PVC, backed with a layer of PSA. Users, often in graphic design industries, can print designs on the film before adhering it to the final product. PE, PP, and PET are widely used for packaging and labeling applications, while PVC is commonly used for outdoor advertising and vehicle wrapping.

Permanent vs. temporary (removable) applications

Although most PSAs are designed to be removable, some are considered permanent. These products slowly increase in bond strength, usually over a period of hours to days. They are initially removable and adhere using electrostatic forces, but over time, the adhesion becomes permanent through chemical, mechanical, or diffusive action.

PSA Materials

Most PSAs are created by combining an elastomer (or elastic polymer) with a tackifier to create a product that is both elastic and viscous at room temperature. Common additives also include plasticizers to adjust softness and viscosity and antioxidants to provide additional weathering resistance.

Rubbers, Resins, and Thermoplastic Elastomers

In these PSA formulations, a rubber is combined with a tackifier to produce a sticky material with excellent tack. Rubber-based products, which are typically applied to a substrate when dissolved in a solvent, are the most common variety of PSA for general use. These products may also be based on thermoplastic elastomers (TPEs), which are typically applied to substrates through the hot melt method.

Rubber-based formulations adhere to a wide variety of materials with high tack, maintain their adhesion over time, and are economical to produce. However, unless specially formulated, their main disadvantage is their generally poor resistance to environmental factors such as heat, chemical exposure, UV light, and oxidation.

Acrylic

Acrylic PSA formulations adhere strongly to polar substrates, such as glass and metal, but can be tailored to adhere effectively to almost any material. Unlike other elastomer bases, some acrylics provide a strong enough tack that no tackifiers are required. These additives are still often used, however, to fine tune the properties of the adhesive and further increase tack.

Acrylic PSAs are highly customizable and offer good resistance to chemical exposure, UV radiation, oxidation, and hydrolysis. They also have a much wider temperature range than rubber-based PSAs, maintaining their properties even below freezing and above boiling temperatures. Their main disadvantages include their higher cost, limited adhesion to low-surface energy (LSE) substrates such as polyolefins, and longer interval of pressure required to reach full strength.

Silicone

Silicone PSAs are the least common and most specialized variety of formulation. They offer excellent resistance to chemical exposure and oxidation, the ability to adhere to both polar and non-polar surfaces, and can maintain their integrity at temperatures exceeding 250°C. Silicone PSAs are preferred for low-surface energy (LSE) substrates and skin contact, such as in medical applications, for gentle removal. Their main disadvantages include their high cost and their weak tack without additives.

Kuraray’s materials for PSAs

In addition to KURARAY LIQUID RUBBER, a range of flexible tackifiers and plasticizers for use in pressure sensitive adhesives, Kuraray offers several other polymers that enhance PSA performance.

KURARAY LIQUID RUBBER

KURARAY LIQUID RUBBER offers a wide variety of grades of liquid polybutadiene rubber (L-BR), liquid polyisoprene rubber (L-IR), and liquid polystyrene-butadiene rubber (L-SBR) for use as tackifiers and plasticizers in pressure sensitive and hot melt adhesives. In addition to the specific strengths of each grade, KURARAY LIQUID RUBBER is a low VOC additive that enhances tack strength and processability.

KURARAY LIQUID RUBBER homopolymer grades of L-BR, L-IR and L-SBR are excellent reactive plasticizers for use in pressure sensitive adhesives and hot melts based on SIS, SBS, and EVA. These grades are well-suited to mobility applications, industrial tape, and medical tape thanks to their good cold temperature resistance, crack resistance, and damping performance. Carboxylated L-IR grades, L-IR-403 and L-IR-410, also support automotive and industrial PSA production by improving adhesion to metals and fibers.

For UV-curable pressure sensitive adhesives and acrylic pressure sensitive adhesives, Kuraray offers two L-IR grades, UC-102M and UC-203M. When used as an additive for PSA formulations, these products offer UV curing, strong tack, good flexibility, toughness enhancement, a low shrinkage ratio, moisture resistance, and permeation resistance while achieving solvent-free or low-VOC coating.

Kuraray’s homopolymer L-BR offers a range of grades for use as reactive plasticizers in pressure sensitive adhesives, while L-SBR serves as a high-performance damping additive in automotive adhesives designed to minimize vibration and noise.

SEPTON™

SEPTON™, a styrenic thermoplastic elastomer, offers a wide range of styrene content and molecular weight variations, enabling optimization of tack, heat resistance, and flexibility in PSA formulations. It can be used in hot-melt and solvent-based adhesives, delivering strong adhesion and excellent durability for diverse applications such as labels, tapes, protective films, and medical adhesives. Kuraray offers the SEPTON™ 2000-series and SEPTON™ 4000-series as various grades of polymer for use in PSA formulations.

HYBRAR™

For applications that require excellent sound damping, such as automotive, rail, marine, and aviation adhesives, Kuraray offers the HYBRAR™ 5000-series. This non-hydrogenated styrenic block copolymer is suitable for use in adhesives, automotive parts, electronics, sealants, and more. Furthermore, HYBRAR™ 7000-series (hydrogenated grades) enhances the performance of olefin-based adhesives. It can provide flexibility to increase re-peelability, cohesion, heat resistance, and even damping properties, making it highly suitable for high performance and specialty functional adhesive formulations.

Production methods

Although almost all PSA products reach the market in a tacky, ready-to-use form that is solid at room temperature, the freshly manufactured adhesive can be applied to its carrier in one of several ways.

Water-based

In this application method, the adhesive is dispersed in water and applied to the substrate. The water is then evaporated, leaving just the adhesive behind. This method is increasingly popular as a low-cost, high-performance, and eco-friendly alternative to solvent-based application. Although it allows for thin coatings and is widely compatible with various PSAs, the resulting product often has poor moisture resistance.

Solvent-based

As in water-based applications, the adhesive is dissolved in a solvent that is applied to the product and then forcibly evaporated, leaving only the PSA behind. Although a wider range of adhesives can be applied this way, solvent-based application is somewhat more expensive and often introduces volatile organic compounds (VOCs) into the process, which can harm the environment, present risks to workers, and be a fire hazard.

Hot melt

Hot-melt PSAs with high viscosity and tack can be melted, applied to a product, and then cooled to their original state. This low-cost method is capable of coating most substrates and can apply a thick layer of adhesive, but is not suitable for thin coatings and results in a product with low heat resistance. Some of these hot melt adhesives are applied during tape and label production, while others are applied for assembly processes.

UV cured

PSAs with low viscosity can be reacted with UV radiation after they are applied to induce further polymerization, increasing their molecular weight to form the final adhesive. This environmentally friendly method avoids solvents, allowing it to build much thicker coatings and be used on substrates that are sensitive to heat or moisture. It remains the least used application method by volume, since it is only compatible with certain low viscosity PSA formulations.

Looking for flexible PSA additives?

Get in touch with our team using the form below to learn more about KURARAY LIQUID RUBBER, SEPTON™, and the benefits of our other elastomer products.

Bonding and attachment methods

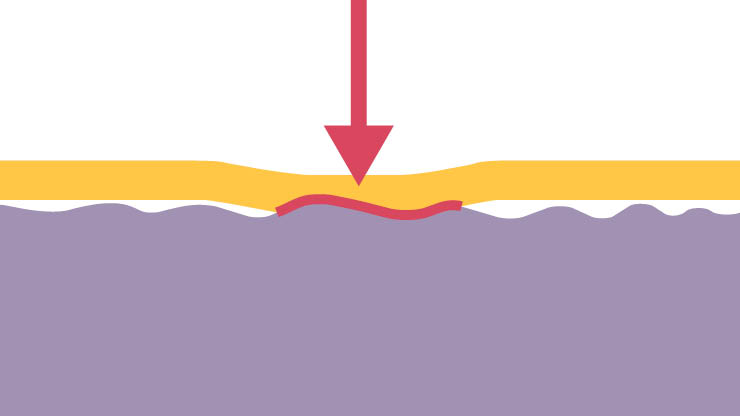

A pressure sensitive adhesive is affixed by simply spreading it flat across a target surface and applying pressure. Some PSAs may also form a stronger bond under greater or longer initial pressure.

Although all PSAs can be applied to a substrate through pressure, each product has its own unique properties that make it ideal for certain applications and suboptimal for others. Aside from cost, there are a variety of factors to consider when choosing a PSA to fit your needs.

Surface energy

A PSA’s compatibility with a surface is determined both by the type of PSA and the substrate’s surface energy. Determine what materials the adhesive will need to stick strongly to when choosing the elastomer base of a PSA formulation.

Tack strength

Depending on the weight or mechanical force the adhesive is expected to support, a PSA may need a higher tack strength. Various formulations offer options for almost any tack, with rubber-based PSA products typically offering the highest tack.

Adhesive thickness

Thicker layers of PSA will generally provide a stronger final product that can adhere to itself more effectively. Other products may require a thinner layer of adhesive. Application methods such as UV curing and hot melt are better suited to applying thick layers of adhesive, while solvent- and water-based methods can produce thinner, more precise layers.

Temperature considerations

In some applications, the PSA may need to maintain its adhesion under higher or lower temperatures. Most PSAs lose their tack at low temperatures and begin to soften and slip at high temperatures, but some are designed to operate under temperatures as low as -60°C and as high as 250°C.

Weathering resistance

Depending on its intended application, a PSA may need to have increased resistance to UV light, water, solvents, oils, oxidation, and other forms of chemical action.

Carrier compatibility

The carrier, or surface on which the PSA will be held before it is used, should also be considered. Some carriers may not be able to withstand the heat of PSAs applied through hot melt or the moisture of those applied through water emulsions.

Pressure required

Some PSA formulations with extremely strong tack require longer or stronger initial applications of pressure to achieve the strongest possible bond. Rubber-based PSAs may be most suitable in applications that need to quickly reach full tack.

Surface treatment

Some surfaces can be treated to make them compatible with a pressure sensitive adhesive that meets all of the other needs of the application. The adhesion of a PSA can be improved by enhancing the wettability of the target surface.

Application industries

Pressure sensitive adhesives are used in a variety of applications across industries, especially in packaging.

Consumer goods, assembly, and packaging

Pressure sensitive adhesives are overwhelmingly used in labels, tapes, assembly, and packaging for most industries—which together account for almost 75% of the PSA market (market.us, 2024). Other predominant consumer goods include graphics, sticky notes, and wall hangings. PSAs used in these applications are often low-cost and easily removed. They may also need to resist low temperatures if used in applications such as frozen food packaging.

Industrial & construction

In the industrial and construction fields, PSAs are used for more than just packaging and assembly. They are also found in specialized tapes, labels, insulation tape, panel and façade bonding, wallpaper, and flooring. PSAs used in these applications must typically have strong tack and heat resistance.

Electronics

As electronics become denser and more powerful, they need thinner adhesives to support increasing miniaturization. High-tack PSA films can be precisely cut to secure printed circuit boards and assemble electronics. PSAs selected for these applications must be resistant to higher temperatures. As another example, dicing tapes are widely used to hold semiconductor wafers in place during dicing and handling processes.

Mobility

Pressure sensitive adhesives are used in the construction of almost every vehicle, from interior paneling and noise dampening to electronics and seals.

Automotive

Pressure sensitive adhesives are critical to automotive assembly. They can be found in interior trim construction, labels, emblems, noise dampening panels, seals, wiring harnesses, electronics, EV batteries, exterior cladding, and surface protection films. These applications often require heat, chemical, oil, water, and oxidation resistance for long-lasting performance.

Rail & marine

The rail and marine industries use PSAs to seal cabins, bond interior panels, affix insulation, and dampen noise. Like automotive PSAs, these applications require water, chemical, and oil resistance, as well as increased vibration dampening capabilities.

Aviation

Aircraft also use PSAs in paneling, insulation, noise dampening, labels, electronics, seals, and more. These high-stakes applications require low-VOC pressure sensitive adhesives that can operate at a wide range of temperatures, as well as water, chemical, oil, and oxidation resistance.

Medical adhesives

Pressure sensitive adhesives are key in medical applications, as no other structural adhesive or fastener is biocompatible, easily removable, and gentle on the skin. PSAs are used in bandages, medical patches, and wearable medical devices, such as heart monitors. In medical tapes and dressings, acrylic-based adhesives are predominant. For skin protection and wound care, rubber-based adhesives (such as hydrocolloids) are widely used. For sensitive skin or situations requiring long-term wear, silicone-based adhesives are used.

Advantages

- Allows for separation of adhesive and surface without damage

- Provides adhesive strength immediately after applying pressure

- Adheres easily in both consumer and industrial settings

- Bonds difficult materials together, regardless of compatibility

- Offers a flexible, light, thin, precise, and invisible fastening method

- Improves assembly times by eliminating curing steps

- Adheres to difficult surfaces, including human skin (medical adhesives)

- Provides uniform adhesive thickness

- Limits health, safety, and disposal concerns

Disadvantages

- Gradually peels under sustained stress

- Limited maximum adhesive strength—not suitable in structural applications or on rough surfaces

- Some varieties are vulnerable to temperature, solvents, and weathering

- Some varieties introduce VOCs into the assembly process

- Moderate cost

Contact