Liquid farnesene rubber

With liquid farnesene rubber, Kuraray is expanding its portfolio of liquid rubbers with a product based on natural and renewable raw materials. It contains a polymerized form of beta-farnesene, a bio-based monomer.

Liquid farnesene rubber functions like a reactive plasticizer, but has a much higher molecular weight than normal plasticizers. The co-vulcanizable material significantly reduces migration, which improves the durability of rubber compounds. Its use during the rubber compounding stage significantly reduces processing time while maintaining the physical properties of rubber compounds. Lower processing costs are the result.

As an additive in rubber compounds, liquid farnesene rubber gives them high plasticity. The material also retains excellent flexibility at low temperatures and improves ice grip. It is therefore currently used mainly in winter tires, where it increases ice grip while preventing the rubber compounds from hardening over time. The performance of the tire is thus maintained over the long term.

How it’s made

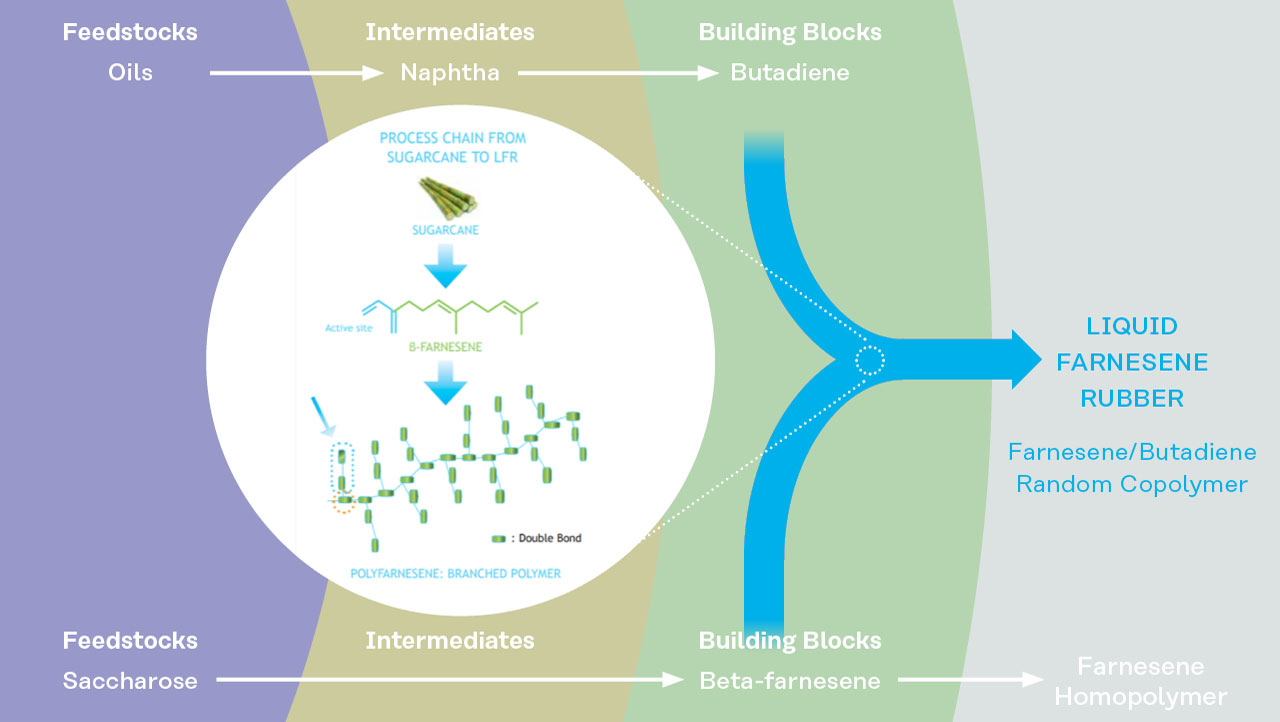

Liquid farnesene rubber is based on beta-farnesene, a renewable monomer derived from sugar cane. Using established fermentation processes, proprietary yeast strains convert sugar sources such as sugar cane into beta-farnesene. Liquid farnesene rubber is synthesized from the base monomer by polymerization.

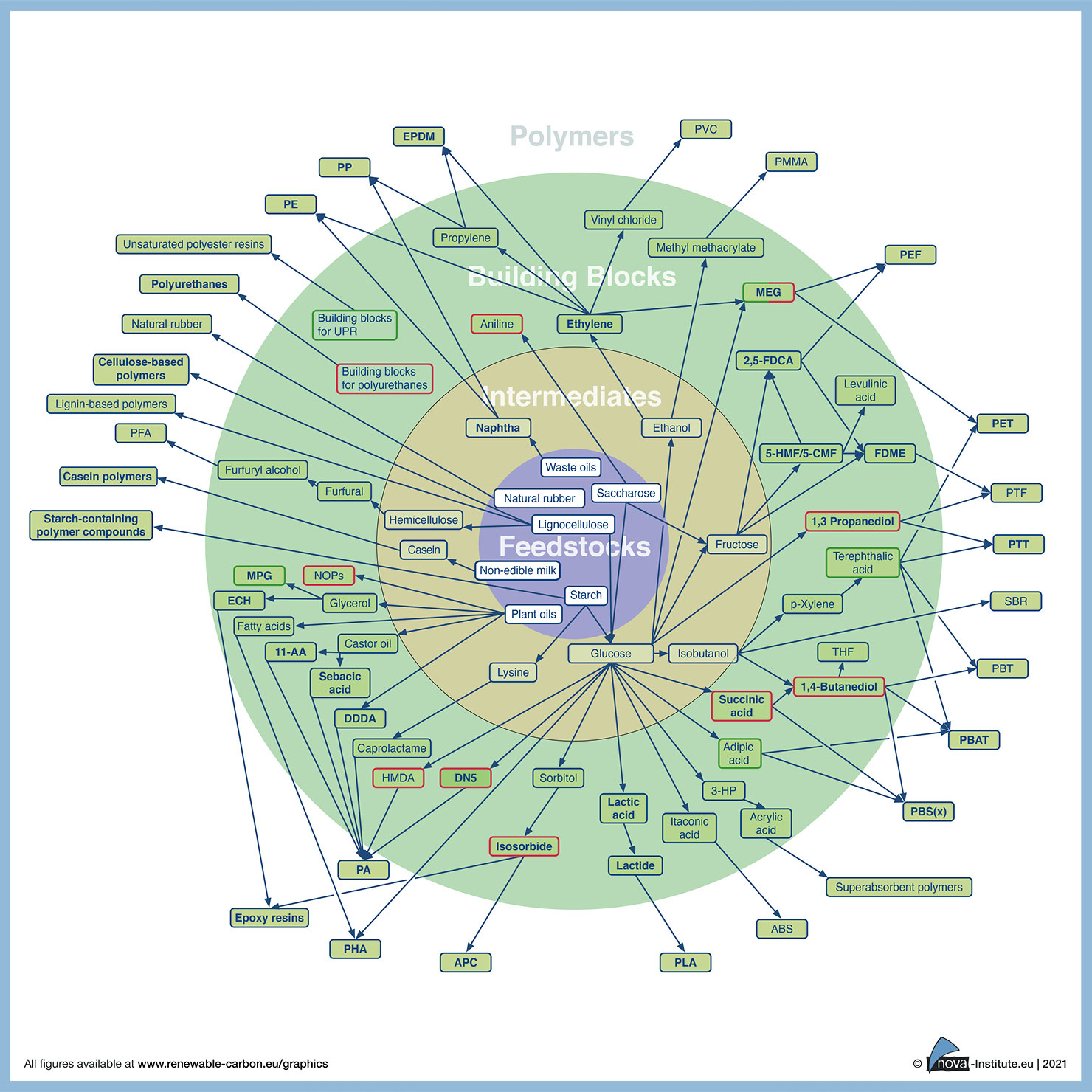

With liquid farnesene rubber, a new family of polymers is created that has unique performance and offers the opportunity to broaden the range of applications for this class of materials. Liquid farnesene rubberthus represents a new pathway to bio-based polymers.

Liquid farnesene rubber is available as homopolymer type (100% beta-farnesene) and as random copolymer type (with a beta-farnesene portion and a crude oil portion). The homopolymer type has a higher molecular weight (130,000) than the two random copolymer types (30,000 and 100,000, respectively). In terms of viscosity, the types differ significantly: homopolymer type (69 Pa•s at 38 °C) and random copolymer types (12 and 603 Pa•s at 38 °C, respectively).

Pathways to bio-based polymers © nova-Institut GmbH

Features & benefits

- Bio-based material

- Good plasticizing effect

- Low migration

- Low tan δ over a wide temperature range

- Excellent softening effect at low temperature (low Tg)

- Less entanglement between molecules

- High reactivity of branched double bonds

- High molecular weight and low viscosity

Applications

- Adhesives, coatings, sealants

- Rubber compounding

- Mobility

- Sporting goods & footwear

For certain applications, liquid farnesene rubber cannot be introduced due to raw material supply relations. Please contact our sales representatives.

Liquid farnesene rubber in tires

The addition of liquid farnesene rubber to the rubber compound improves the performance and service life of tires. The material is used primarily in winter tires. Liquid farnesene rubber retains its elasticity, especially at lower temperatures, and thus provides optimum grip on snowy and icy roads. Tire manufacturers also benefit from faster crosslinking and lower viscosity, resulting in a more efficient production process.

The special structure of highly branched molecular chains reduces entanglements and results in lower viscosity compared to liquid isoprene rubbers. Thanks to its optimum molecular weight, liquid farnesene rubber reacts completely with the solid rubber during vulcanization, sulfur and peroxide. Unlike oil, which migrates to the surface of the rubber over time, preventing it from softening, liquid farnesene rubber remains fixed in the rubber compound. Therefore, the performance of the tires remains stable for a very long time.

Tire manufacturers also benefit from the rapid cross-linking of liquid farnesene rubber. Its good co-reactivity ensures rapid vulcanization. This enables shorter processing cycles, lower energy consumption and higher processing rates. With its special properties, liquid farnesene rubber enables the development of tires that reduce vehicle fuel consumption, generate less heat and bring vehicles to a halt safely even on icy surfaces.

Features & benefits

- Improved processing properties and efficiency

- Glass transition temperature (Tg) control enables improvement of ice grip performance

- Much lower viscosity compared with current liquid isoprene rubber

- High plasticity of the rubber compound

- Excellent flexibility even at low temperatures

Applications within tires

- Tire treads (Replacement of resins or oils)

- Bead filler

- Under-cushion

- Under-tread

Ethical

Manufactured from renewable resources and easy to process, liquid farnesene rubber increases efficiency and sustainability in tire production. By increasing the organic content in the final product, the material will contribute to a more sustainable world.

Liquid farnesene rubber is sustainably synthesized from beta-farnesene derived from Bonsucro-certified sugar cane. The Bonsucro certification system is a global and non-profit multi-stakeholder initiative that aims to reduce the negative environmental and social impacts of sugar cane production while addressing the need for economic viability.

The Bonsucro Production Standard applies to mills and their sugar cane supply areas. It includes principles, criteria and indicators that measure sustainable sugar cane production. The first five principles assess sustainability in the sugar cane industry. The indicators measure the economic, social and environmental impacts of sugar cane and help ensure that mills and their suppliers produce sugar cane and derived products sustainably.

The use of food crops for the production of bio-based polymers leads to recurring and often emotionally charged debates. Liquid farnesene rubber, however, unlike food crop-based polymers, does not exacerbate the global hunger problem because its feedstock, sugar cane, is a so-called cash crop. While food crops, such as cereals or potatoes, are grown to provide food for human consumption, cash crops, such as sugar cane or coffee, are grown mainly for the international market, mostly for direct consumption but also as raw materials for the processing industry.

Sustainability brochure

KURARAY LIQUID RUBBER:

Liquid farnesene rubber

Technical insights

You can find more information about our products and applications in the R&D documentation.

Contact