Liquid farnesene rubber

凭借liquid farnesene rubber,可乐丽推出基于天然和可再生原材料的产品扩大了液态橡胶的产品组合。它含有聚合形式的 β-法呢烯,是一种生物基单体。

Liquid farnesene rubber的功能类似反应性增塑剂,但它的分子量比普通增塑剂高得多。共硫化材料显著减少迁移,提高了橡胶化合物的耐久性。它在橡胶混炼阶段的使用显著减少了加工时间,同时保持了橡胶化合物的物理特性,而且可实现更低的加工成本。

作为橡胶化合物中的添加剂,liquid farnesene rubber赋予它们更高的可塑性,更可以在低温下保持出色的柔韧性,提高冰抓地力。它目前主要用于冬季轮胎,增加冰上抓地力,同时防止橡胶化合物随着时间的推移而硬化。因此,轮胎的性能得以长期保持。

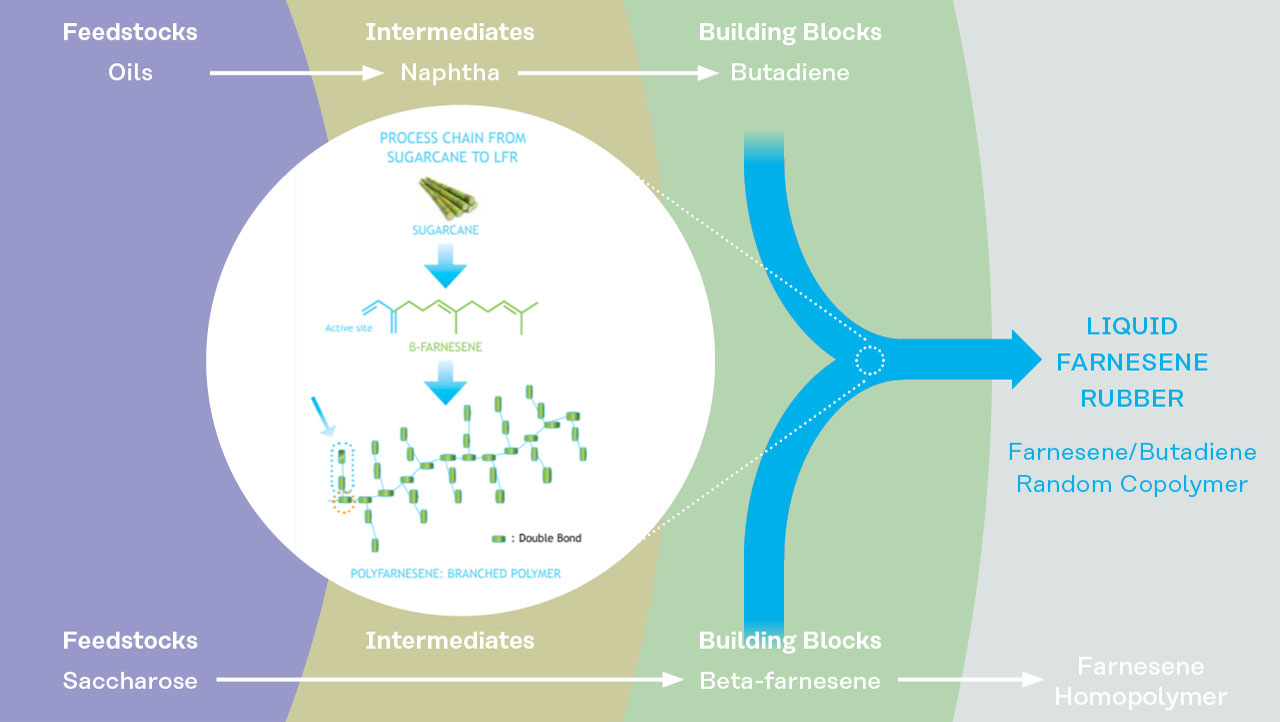

制造原理

Liquid farnesene rubber基于β-法呢烯制成,β-法呢烯是一种源自甘蔗的可再生单体。然后采用成熟的发酵工艺,令专有酵母菌株将甘蔗等糖源转化为 β-法呢烯。Liquid farnesene rubber是由基础单体通过聚合反应合成的。

Liquid farnesene rubber创造了一种具有独特性能的新型聚合物,扩大了此类材料的应用范围。因此,liquid farnesene rubber代表了一条通往生物基聚合物的新途径。

Liquid farnesene rubber分为均聚物类型(100% β-法呢烯)和无规共聚物类型(具有β-法呢烯部分和原油部分)。均聚物类型的分子量 (130,000) 高于两种无规共聚物类型(分别为 30,000 和 100,000)。在粘度方面,两者的类型差异很大,均聚物型在38°C 时为 69 Pa•s,而无规共聚物型在38 °C 时为 12 和 603 Pa•s)。

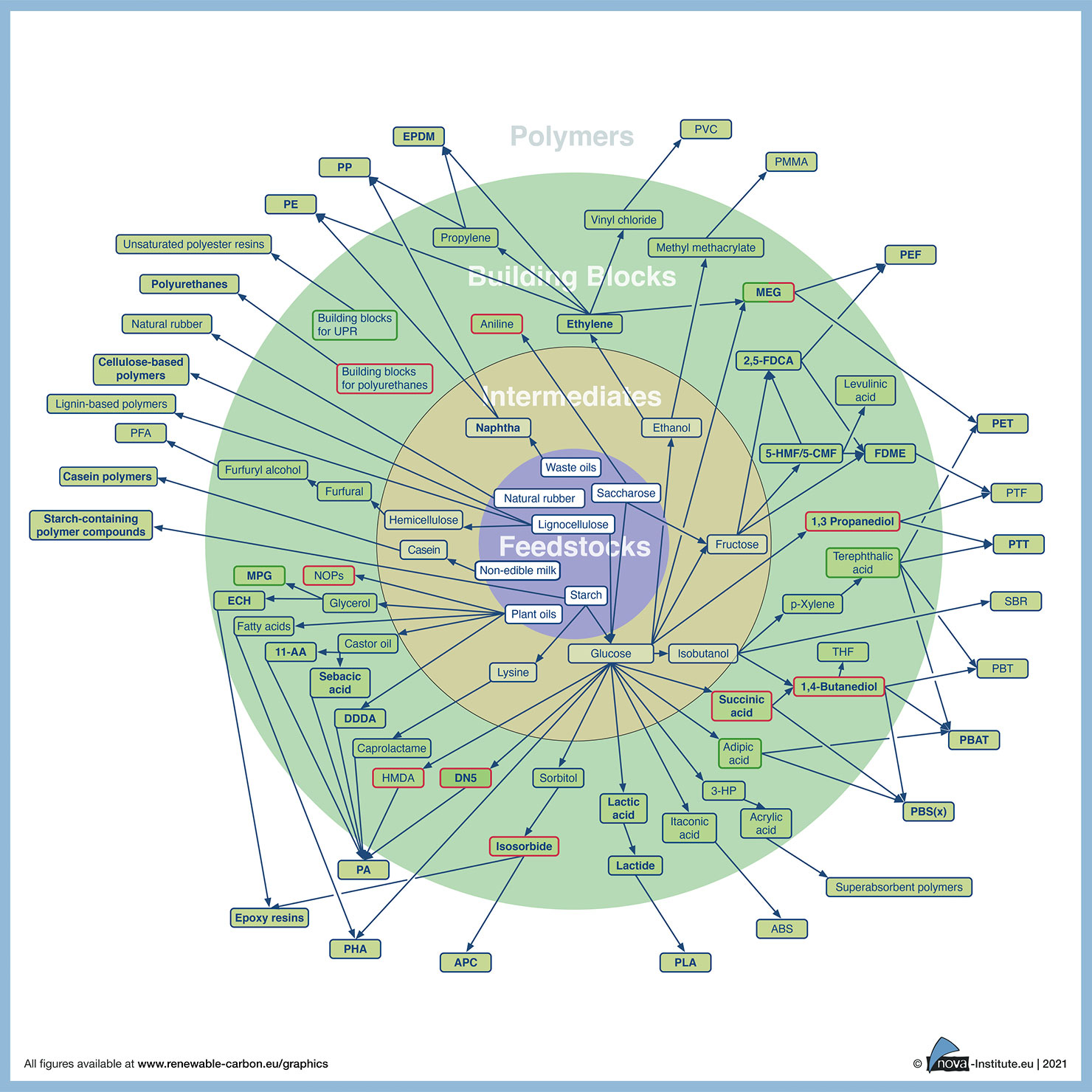

生物基聚合物的途径 © nova-Institut GmbH

特点和优点

- 生物基材料

- 塑化效果出色

- 低迁移率

- 在宽温度范围内具有低 tan δ

- 出色的低温软化效果(低 Tg)

- 减少分子之间的纠缠

- 支化双键的高反应性

- 高分子量和低粘度

应用

- 粘合剂、涂料、密封剂

- 橡胶混炼

- 流动性

- 体育用品和鞋类

由于原料供应方面的关系,liquid farnesene rubber被限制应用于某些用途。具体请联系产品销售。

在轮胎中应用liquid farnesene rubber

在橡胶化合物中添加liquid farnesene rubber可提高轮胎的性能和使用寿命。该材料主要用于在冬季使用的轮胎。Liquid farnesene rubber可保持轮胎的弹性,尤其是在较低温度下,在冰雪路面上增加抓地力。轮胎制造商还受益于更快的交联和更低的粘度,提高生产过程的效率。

与液体异戊二烯橡胶相比,高度支化分子链的特殊结构减少了缠结,降低粘度。由于其最佳分子量,liquid farnesene rubber在硫化过程中与固体橡胶、硫磺和过氧化物能完全反应。不像油会随着时间的推移而迁移到橡胶表面防止其软化。Liquid farnesene rubber可固定在橡胶混合物中。因此,轮胎的性能可以长时间保持稳定。

轮胎制造商也受益于liquid farnesene rubber的快速交联。其良好的共反应性确保了快速硫化。这可以实现更短的加工周期、更低的能耗和更高的加工速率。凭借liquid farnesene rubber的特殊性能,制造商能开发降低车辆油耗、产生更少热量并且即使在结冰的路面上也能安全停车的轮胎。

特点和优点

- 改进的加工性能和效率

- 玻璃化转变温度 (Tg) 控制可提高冰抓地性能

- 与目前的液态异戊二烯橡胶相比有更低的粘度

- 橡胶混合物的高可塑性

- 即使在低温下也具有出色的柔韧性

轮胎中的应用

- 轮胎胎面(替换树脂或油)

- 填缝剂

- 胎垫

- 胎纹

合乎道德

liquid farnesene rubber采用可再生资源制造且易于加工,可提高轮胎生产的效率和可持续性。通过增加产品中的有机含量,为可持续发展的世界做出贡献。

Liquid farnesene rubber是由经 Bonsucro 认证的甘蔗衍生的β-法呢烯可持续合成的。 Bonsucro 认证系统是一项全球性的非营利性多利益相关方倡议,旨在减少甘蔗生产对环境和社会的负面影响,同时满足经济可行性的需求。

Bonsucro 生产标准适用于工厂及其甘蔗供应区。 它包括衡量可持续甘蔗生产的原则、标准和指标。 前五项原则评估了甘蔗行业的可持续性。 这些指标衡量甘蔗对经济、社会和环境的影响,并有助于确保工厂及其供应商以可持续的方式生产甘蔗和衍生产品。

使用粮食作物生产生物基聚合物引发了社会争论。 然而,liquid farnesene rubber与基于粮食作物的聚合物不同,不会加剧全球饥饿问题,因为其原料甘蔗是所谓的经济作物。谷物或马铃薯等粮食作物的种植是为人类消费提供食物,而甘蔗或咖啡等经济作物的种植主要用于国际市场,主要用于直接消费,也可作为加工业的原材料。

可持续发展手册

KURARAY LIQUID RUBBER:

Liquid farnesene rubber

联系我们