Oil additives for cost-effective, high-performance formulations

SEPTON™, Kuraray’s high-performance hydrogenated styrene block copolymer, and KURARAY LIQUID RUBBER, are oil additives that enable formulations at a lower cost with improved shear stability, low-temperature performance, and oil retention.

Applications include engine oils, specific gear oils, hydraulic fluids, and various types of grease. Let us walk you through how our products make this possible.

| Application | SEPTON™ | KURARAY LIQUID RUBBER |

| Engine Oil | ✓ | - |

| Gear Oil (Transmission Fluid) | - | ✓ |

| Hydraulic Fluid | - | ✓ |

| Lithium Grease | ✓ | - |

Benefits of Kuraray’s oil additives

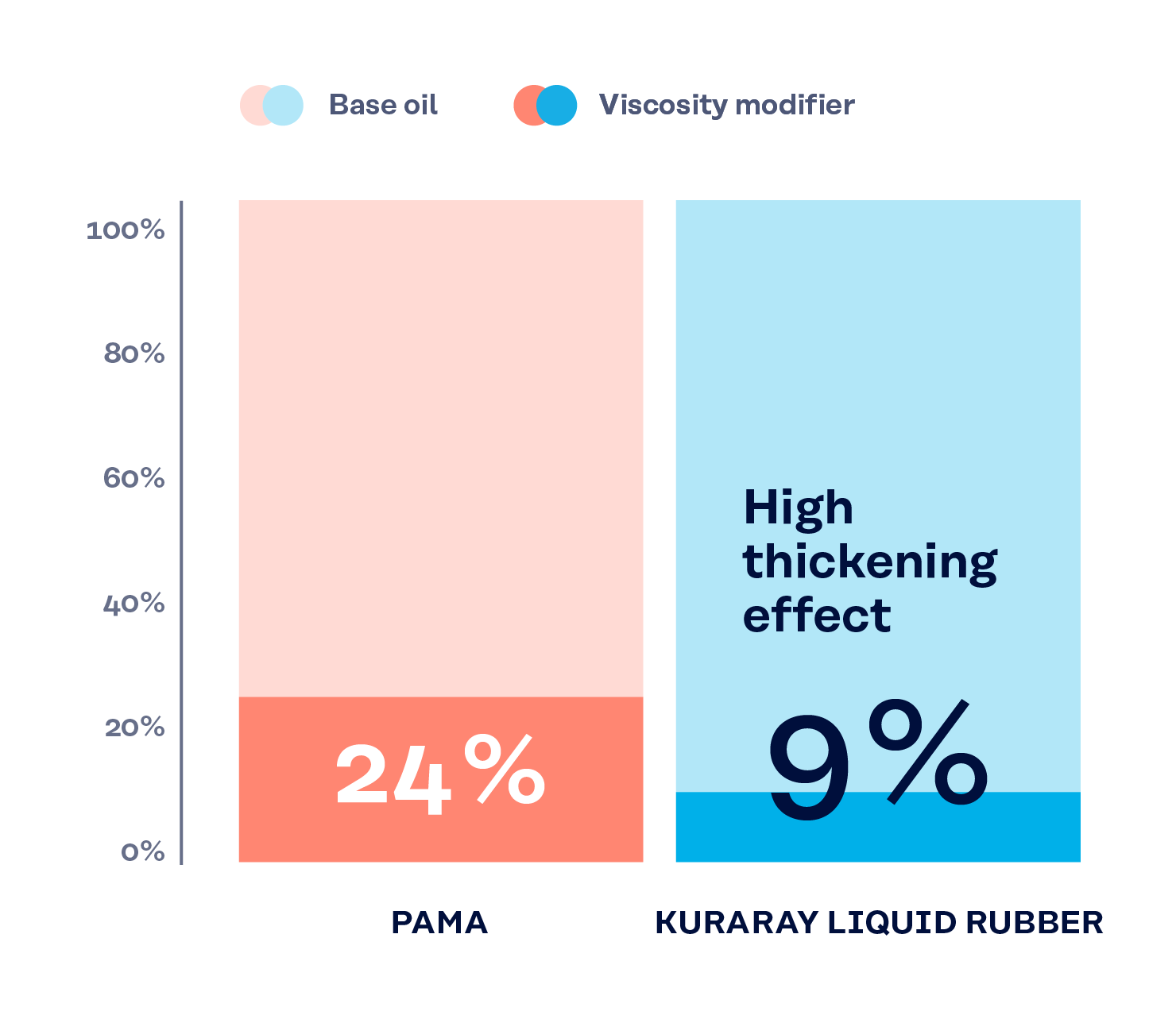

High thickening efficiency

Efficient thickening is one of the most important factors for viscosity index improvers. For cost reduction purposes, the use of oil additives should be minimized, but maintaining the required viscosity is a must—the selection of an appropriate viscosity index improver becomes essential.

For example, KURARAY LIQUID RUBBER can achieve the target viscosity in a 75W-90 gear oil formulation with an addition amount of 9.0 wt%. A competing product, PAMA, requires an addition of 23.5 wt% to achieve the same viscosity.

SEPTON™, a styrene-based thermoplastic elastomer, is also a highly functional oil additive in engine oil applications: It exerts a thickening effect even with an addition amount of as little as 1.3 wt% in a 10W-30 formulation. A competing product, OCP, requires an addition of 10.1 wt%. One of the major advantages of Kuraray’s products is that they can achieve efficient thickening with just a small amount added.

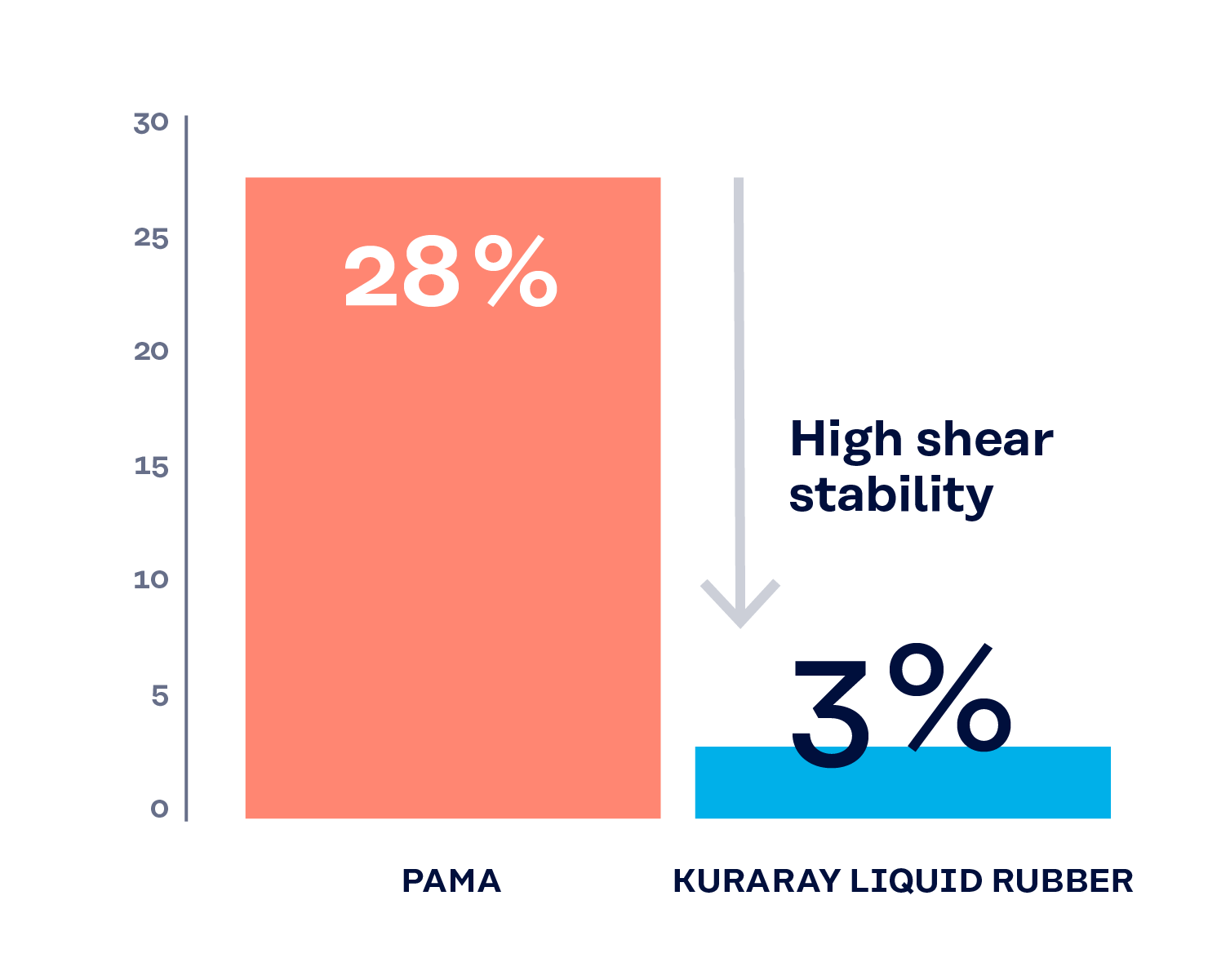

High shear stability

Another critical aspect of oil performance is shear stability—the ability of an oil to maintain its viscosity under mechanical stress. Oils that resist viscosity loss during shear are essential for reliable and consistent operation.

A key advantage of Kuraray’s oil additives is their ability to deliver high shear stability alongside efficient thickening. For instance, a formulation containing 9 wt% of KURARAY LIQUID RUBBER exhibits a remarkably low Shear Stability Index (SSI) of just 2.8%, indicating minimal viscosity change under shear stress.

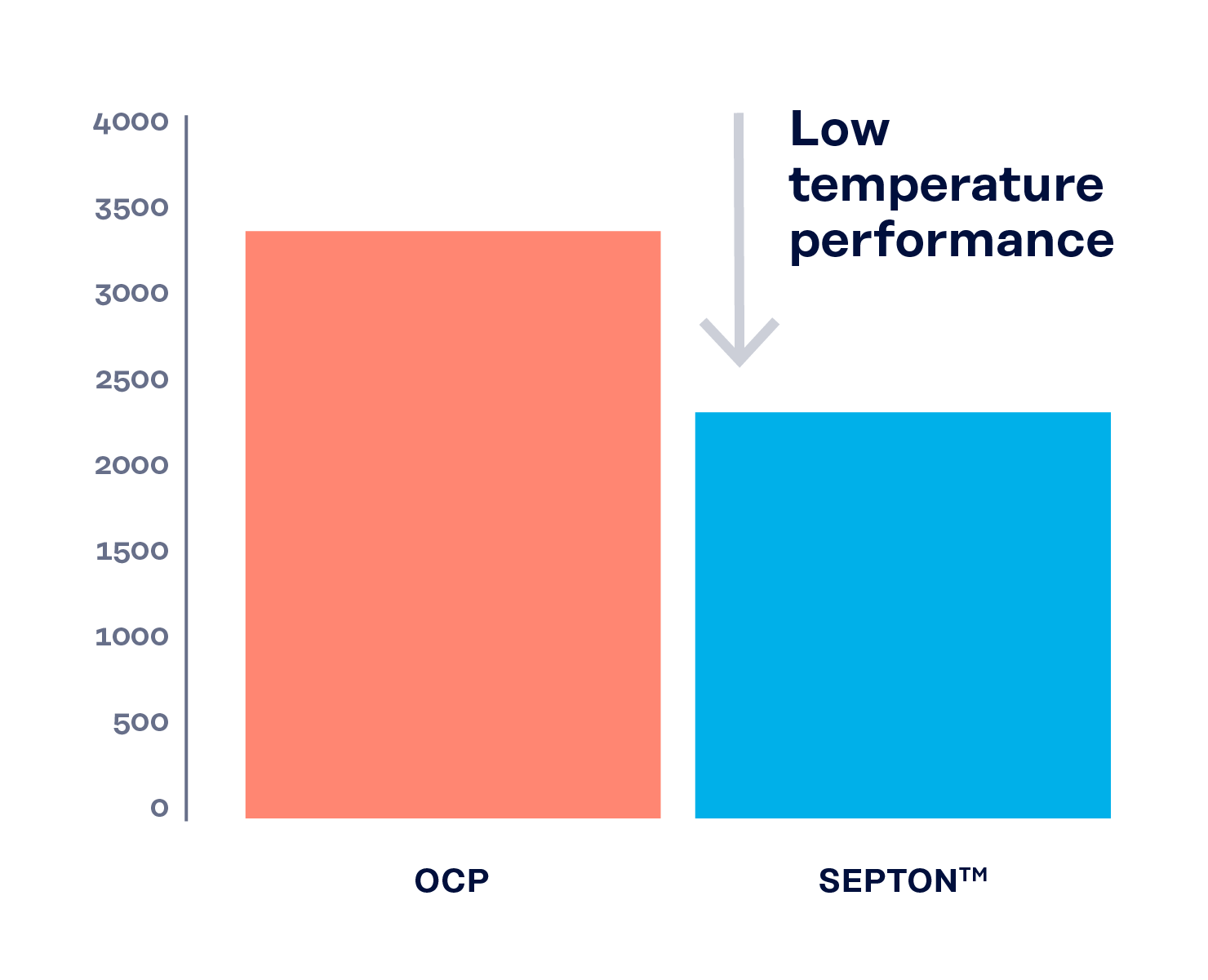

Excellent low temperature performance

In cold climates, lubricants must perform reliably at low temperatures. Hence, maintaining consistent performance in cold environments becomes a key factor when choosing an oil modifier.

For example, in an engine oil formulation with SEPTON™ added, the cold-cranking simulator (CCS) viscosity at -25 °C is just 2,400 mPa·s. This low value means the oil stays fluid and easy to pump in cold conditions—helping ensure smoother engine starts and better overall efficiency compared to competing products.

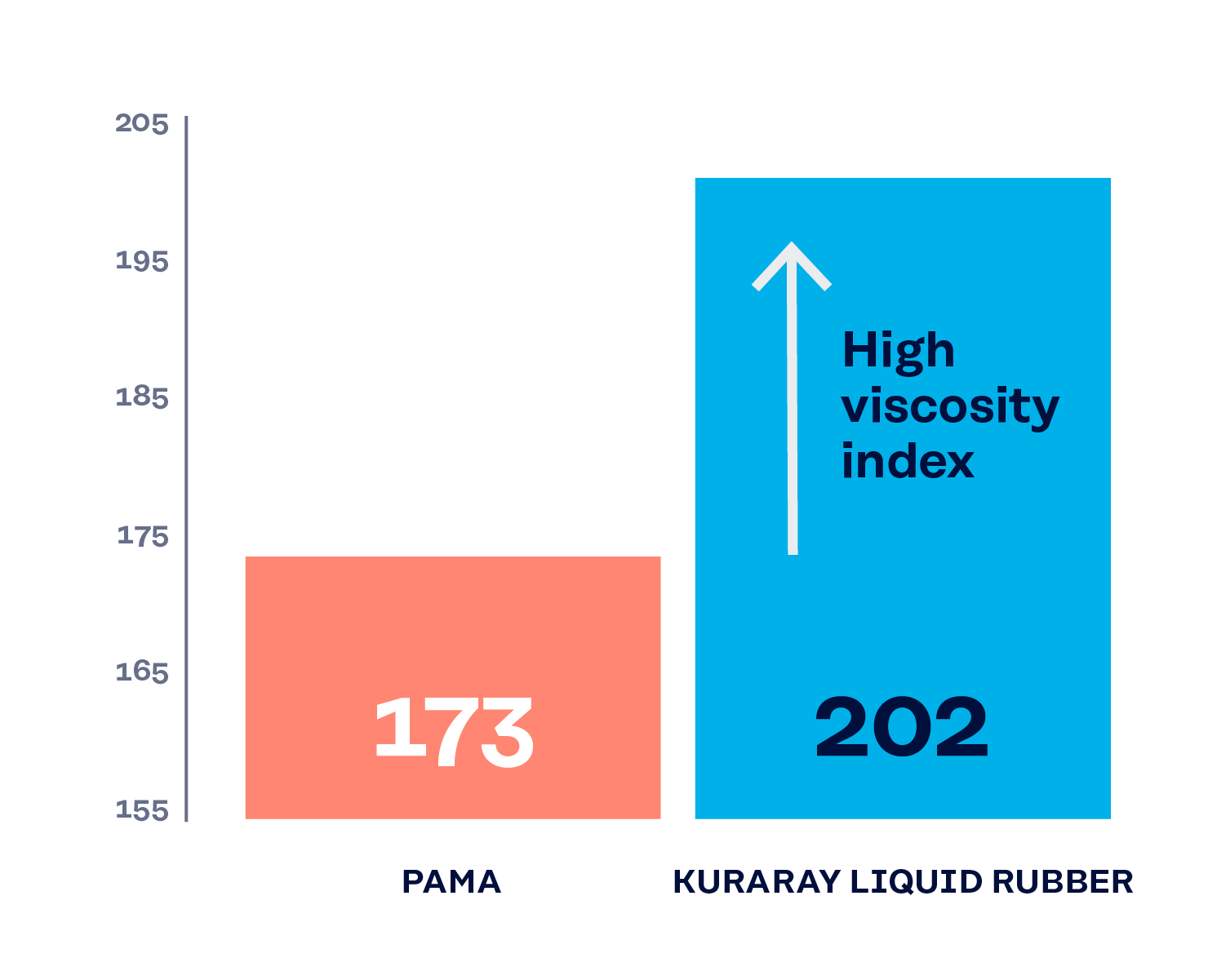

High viscosity index

One standout advantage of KURARAY LIQUID RUBBER and SEPTON™ is their high viscosity index. For instance, a 75W-90 gear oil formulation incorporating KURARAY LIQUID RUBBER achieves a viscosity index of 202—substantially higher than that of conventional alternatives like PAMA, which typically reach around 173.

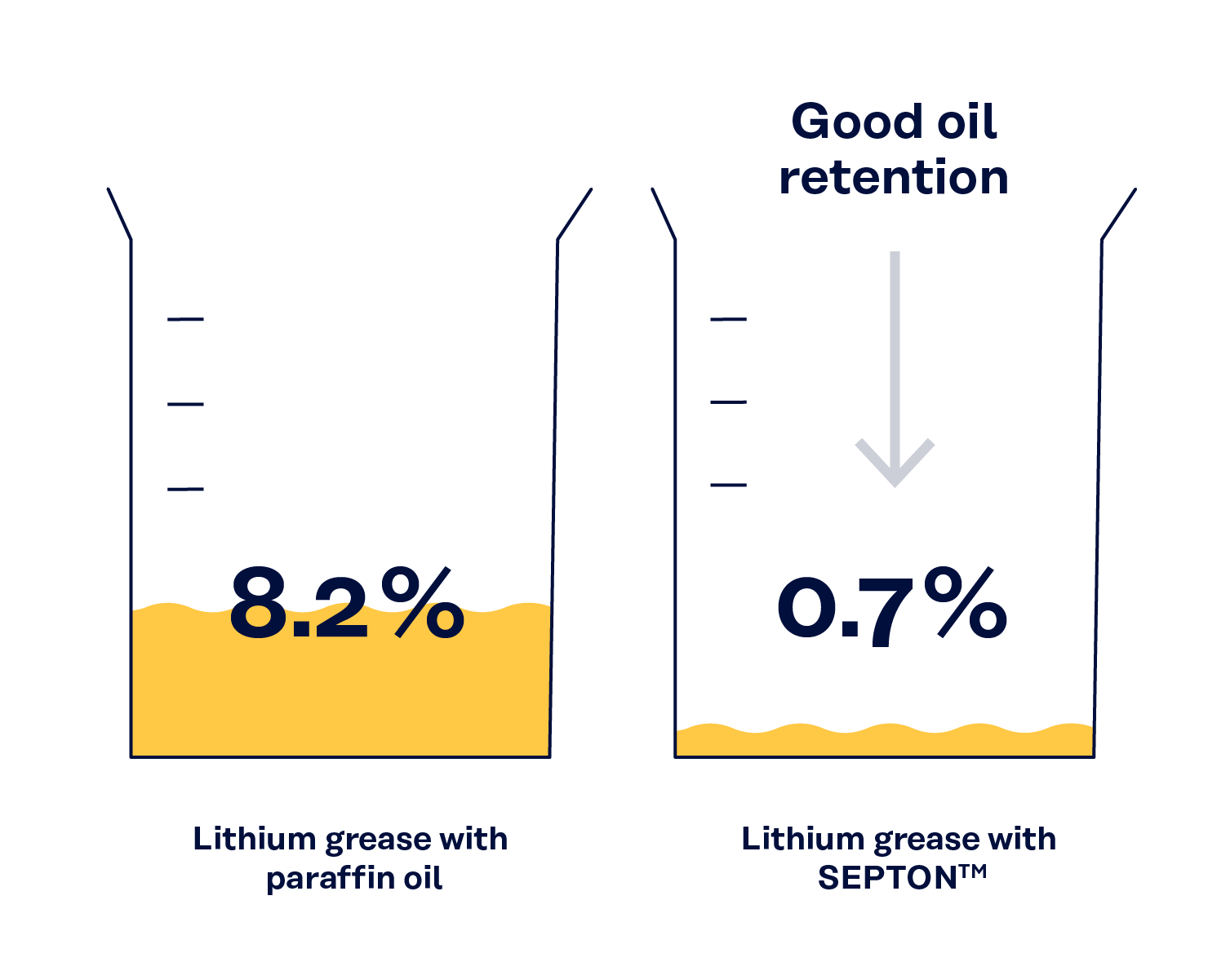

Good oil retention for lithium grease

Lithium grease is widely used due to its excellent heat resistance, water resistance, and shear stability. However, it is typically formulated with paraffin oil, which can lead to oil separation over time—especially in high concentrations. This is where SEPTON™ makes a difference. Known for its exceptional oil retention, SEPTON™ can significantly reduce oil separation—from 15% down to just 0.7%—helping to stabilize the grease’s physical properties over time.

In addition, rising prices of lithium hydroxide, a key raw material in lithium grease, have prompted the need for cost-saving alternatives. By incorporating Kuraray’s SEPTON™, manufacturers can partially replace lithium hydroxide while still maintaining—if not enhancing—the grease’s performance.

¹ in 75W-90 formulation

² PSSI at 100 °C, 75W-90 formulation, by CLC-L45-99 method

³ CCS viscosity at -25 °C, in SAE 10W-30 engine oil formulation

⁴ Viscosity index in 75W-90 formulation

⁵ Oil separation degree at 100 °C, 24h

Downloads

Oil additives brochure

For detailed technical information and formulation examples, please click here:

Contact us

Get in touch

Would you like to understand how our products improve oil formulations at the molecular level or request a sample? We are happy to help—just get in touch with us.

Contact